CSD6305DF Induction-Type ESD Ionizing Air Snake for Electronics Cleanroom

CSD6305DF Induction-Type ESD Ionizing Air Snake for Electronics Cleanroom

● Mobel: 1150D

● MOQ : 1 set

● Packing details:

● Subject to discussion:

Không thể tải khả năng nhận hàng tại cửa hàng

Introducing the CSD6305DF Induction-Type ESD Ionizing Air Snake

Static electricity can cause damage, defects, and downtime in sensitive production environments. The CSD6305DF Induction-Type ESD Ionizing Air Snake is a powerful yet compact static eliminator designed to neutralize electrostatic charges efficiently and safely. Featuring high-frequency ionization, fast discharge speed, and adjustable airflow, this ionizing air blower ensures clean, ESD-safe conditions in electronics manufacturing, cleanrooms, labs, and assembly lines.

Operating at 110V/60Hz or 220V/50Hz with a 26W motor, this static removal tool offers consistent ion output and rapid discharge in a lightweight, ergonomic design. Backed by a 1-year warranty, video outgoing inspections, and machinery test reports, the CSD6305DF delivers peace-of-mind quality and performance.

Key Features & Performance

High-Frequency Static Elimination

The ionizing air snake employs induction-style high-frequency ionization to release a balanced stream of positive and negative ions. With ion balancing precision of ≤±50V at 150 mm, the device neutralizes electrostatic charges on surfaces effectively—preventing ESD damage, dust clinging, and particle attraction.

Fast Discharge Speed

Experience rapid static elimination in ≤1.5 seconds upon activation. Ideal for environments where quick mitigation is essential to maintain production flow and product integrity.

Adjustable Pressure & Range

Fine-tune the ionizing performance with air pressure adjustable between 0.2–0.6 MPa, suitable for various materials and distances. With an effective working distance of 150–300 mm, this versatile tool neutralizes charges on PCBs, plastic parts, and finished assemblies.

Low Noise, Wide Operation

At ≤45 dB, the device ensures quiet operation, suitable for noise-sensitive labs, offices, or cleanrooms. Designed to perform in temperatures from –10 °C to 50 °C, it delivers ESD control throughout indoor environments.

Lightweight, Portable Design

Weighing just 4.5 kg, and measuring 25 × 30 × 20 cm, the ionizing air snake is easy to integrate into workstation environments. Its flexible nozzle design gives precise targeting—eliminating static from complex or hard-to-reach areas.

Technical Specifications

| Feature | Detail |

|---|---|

| Product Name | Induction-Type Ionizing Air Snake |

| Model | CSD6305DF |

| Voltage | 110V/60 Hz or 220V/50 Hz |

| Power | 26W |

| Ion Balance | ≤±50V @ 150 mm |

| Discharge Time | ≤1.5 seconds |

| Air Pressure | 0.2–0.6 MPa |

| Working Distance | 150–300 mm |

| Noise Level | ≤45 dB |

| Operating Temp | –10 °C to 50 °C |

| Weight | 4.5 kg |

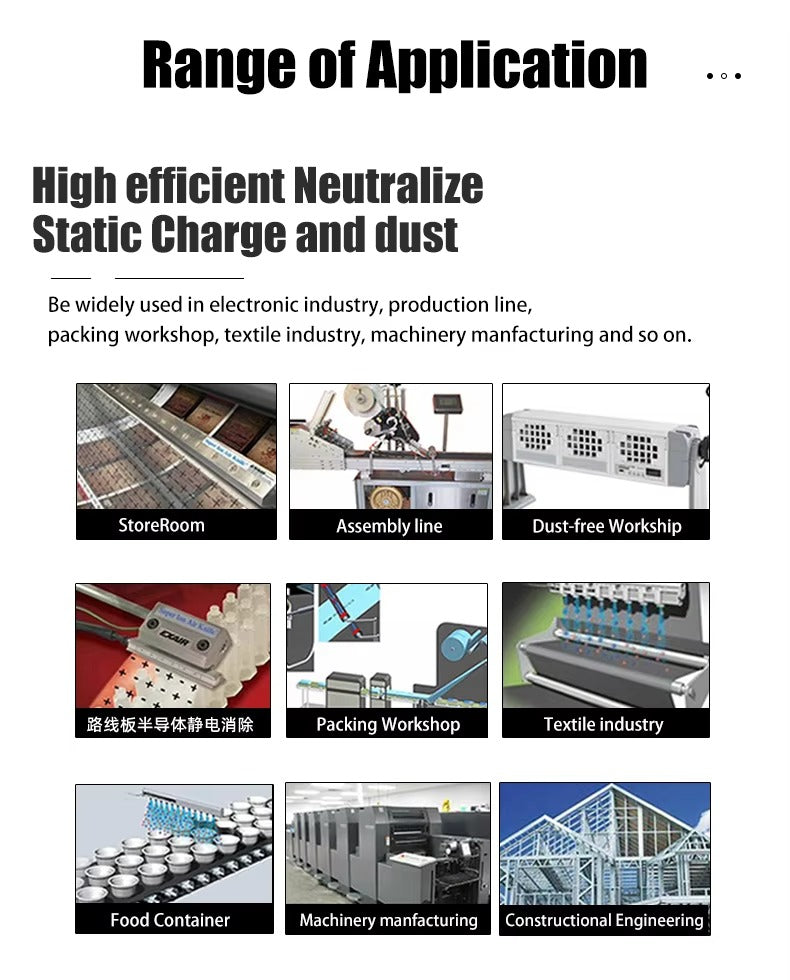

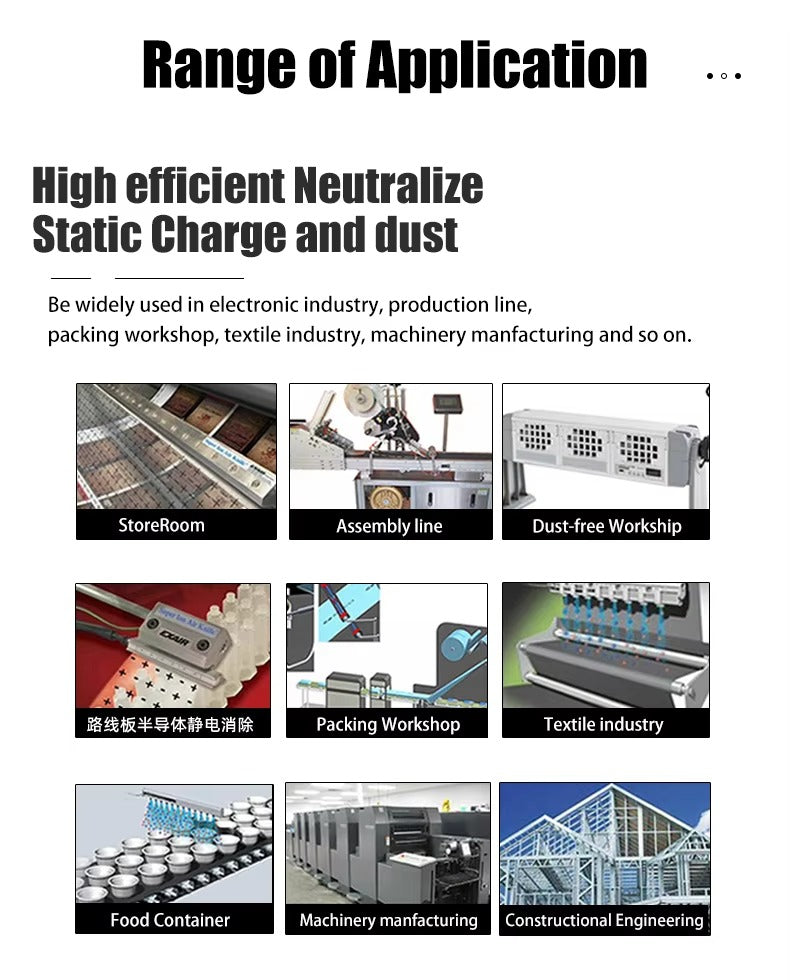

Ideal Applications

1. Electronics Manufacturing & PCB Assembly

Neutralize static on circuit boards during soldering, placement, and QC, safeguarding against ESD damage that causes failure or field returns.

2. Semiconductor & Optics Cleanrooms

Maintain precision workstations where static attracts microscopic dust or particles that compromise optical performance or semiconductor yields.

3. Plastic Molding & Injection Shops

Ionizing blower prevents static cling on molded parts, enabling dust-free handling, packaging, and assembly.

4. 3D Printing & Laser Workshops

Combat static buildup on printed parts. Enhance print quality and reduce dust attracting, improving surface finish and consistency.

5. Medical Device & Healthcare Assembly

Protect sensitive plastic and electronic components with safe ionizing air that ensures cleanliness and compliance.

6. ESD-Controlled Workstations

Deploy on production or inspection benches to neutralize residual charge before final testing or packaging.

Benefits You Gain

-

Improved Yield & Quality

Reduce ESD-related defects and component damage—resulting in fewer rejects and higher profitability. -

Faster Production Throughput

Quick discharge and adjustable airflow streamline handling after soldering or placement operations. -

Health & Cleanroom Compliance

Low ozone emissions and reduced particle attraction meet cleanroom standards and maintain air purity. -

Durability & Low Maintenance

Designed for heavy industrial use with reliable performance, backed by inspection documentation. -

Compact & Easy Integration

Lightweight design fits existing production lines and is easy to reposition as needs change.

Packaging & Supply

Each unit is securely packed in a compact carton (25 × 30 × 20 cm) with a net weight of 3.5 kg. Ideal for domestic or international shipping.

Lead Time Schedule:

| Quantity (pcs) | Lead Time |

|---|---|

| 1–2 | 8 days |

| 3–50 | 14 days |

| 51–200 | 21 days |

| >200 | Negotiated |

With OEM and branding support available, large orders are fully supported via our 150k-unit monthly production capacity.

——————————

JIT Industrial Asia Pte Ltd | Solutions for Manufacturing Industry

Providing equipment and technology solutions for the electronics manufacturing and automation industries.

Address 1: No.4, Lane 82, Dich Vong Hau, Cau Giay, Hanoi, Vietnam

Address 2: No 6, M1, Phuoc Long B, TP. Thu Duc, TP. Ho Chi Minh

Email: info@jitvietnam.com | Hotline: (+84) 34 810 0358