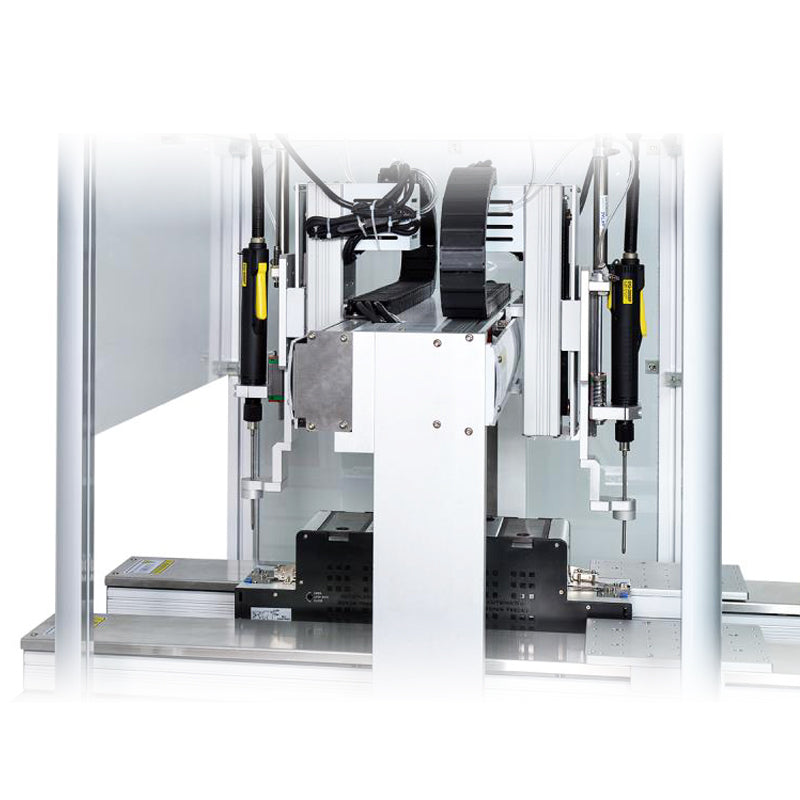

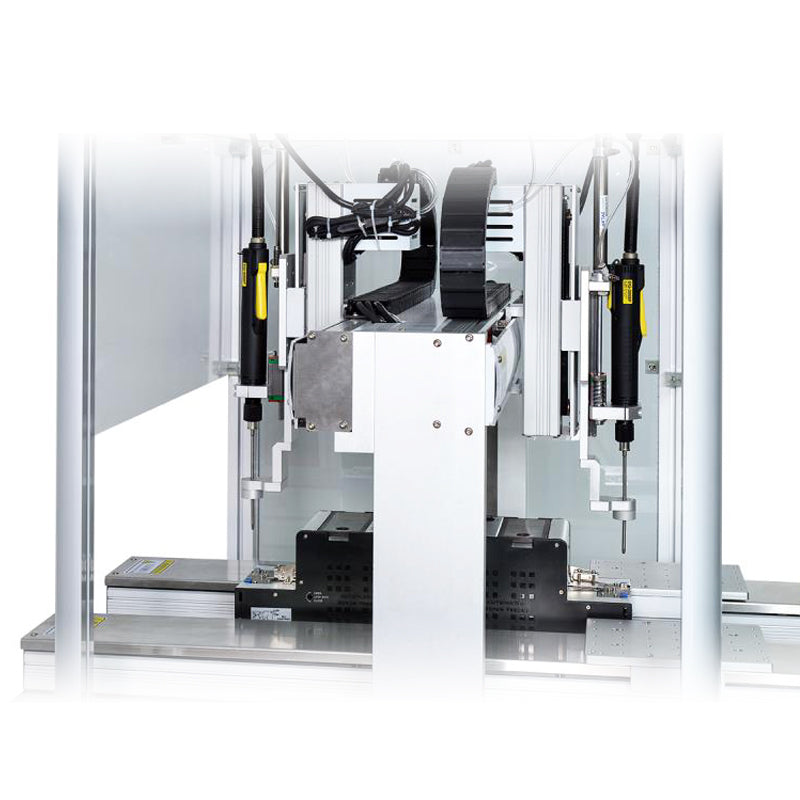

WT-7024-2Z Screw Fastening Robot (Magnetic Suction type))

WT-7024-2Z Screw Fastening Robot (Magnetic Suction type))

● Mobel: 1150D

● MOQ : 1 set

● Packing details:

● Subject to discussion:

Couldn't load pickup availability

WT-7024-2Z (Magnetic Suction type)

Screw Fastening Robot

Screw Fastening Robot greatly improves the work efficiency and the screw fastening consistancy & reliability. With the advanced Teaching Pendant, operators can set up by themselves all the process parameters such as the screw coordinate and screw types, etc. It can adapt to all sorts of difficult screw fastening process and achieve the complete automation.

Features:

1. Permanent magnetic suction (vacuum suction), to achieve fast feeding and screwing.

2. The operator can use manual positioning to do the programming. It is highly efficient and very easy to learn the operation.

3. With alarm function for fastening missing, untightened screws, worn thread, etc.

4. Support auto sensing start operation function.

5. With the fixed work table, the working position can be adjusted flexibly.

Applications:

It is suitable for all kinds of screw fastening process on mobile phones, keyboards, monitors, car accessories, toys, small home electrical appliances, integrated circuits, printed circuit boards, LCD screen, electronic components (such as relays, speakers), etc.

Model |

WT-7024-2Z |

Operating Range (X * Y * Z) |

|

Movement Speed |

|

Repeatability Accuracy |

|

|

|

|

|

|

|

|

|

|

|

|

|

Weight |

|