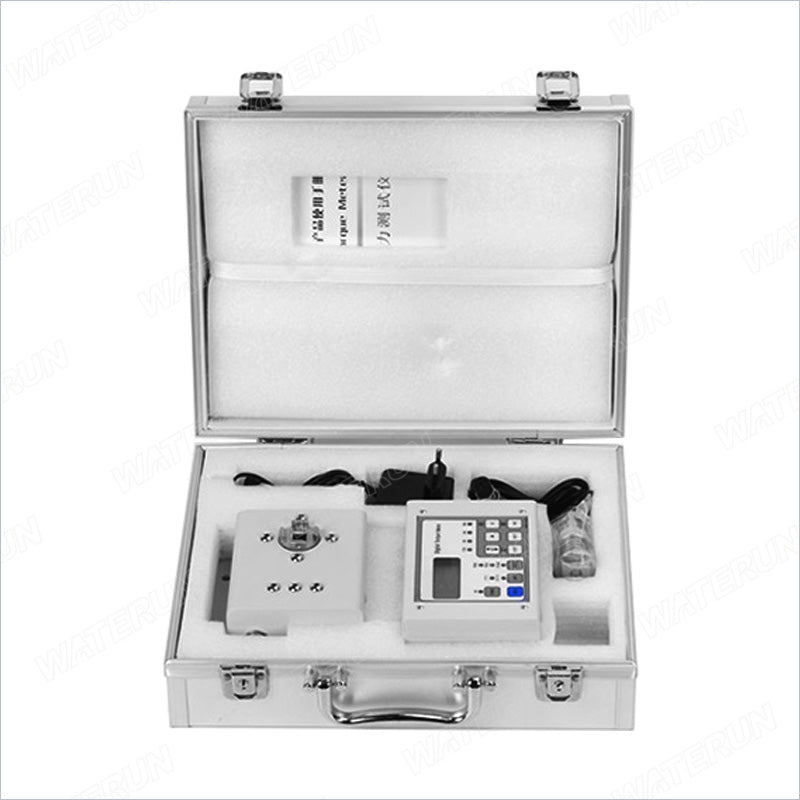

HIT Series Digital Torque Meters (Split Type)

HIT Series Digital Torque Meters (Split Type)

● Mobel: 1150D

● MOQ : 1 set

● Packing details:

● Subject to discussion:

Couldn't load pickup availability

Features:

1.Specially designed for management of torque for impact drivers.

2.First peak measuring mode(F.PEAK) gives precision measurements of torque wrenches or other tools.

3.Confirm peak, FP mode value by buzzer.

4.Data output and analog output are standard spec. characteristics.

| Model | HIT-10 | HIT-100 | HIT-300 | HIT-50 | |

|

Measurement Range |

Kgf.cm |

0.15-10.0 |

1.5-100.0 | 10.0-300.0 | 15.0-500.0 |

| N.m | 0.015-1.0 | 0.15-10.0 |

1.0-30.0 | 1.5-50.0 | |

| Accuracy | within±0.5% |

within±1.0% |

|||

| Measuring Modes | Peak, Track, First Peak | ||||

| Dimensions (mm) | 123 (W) x 230 (D) x 65 (H) | ||||

| Weight |

1.8 kg

|

||||